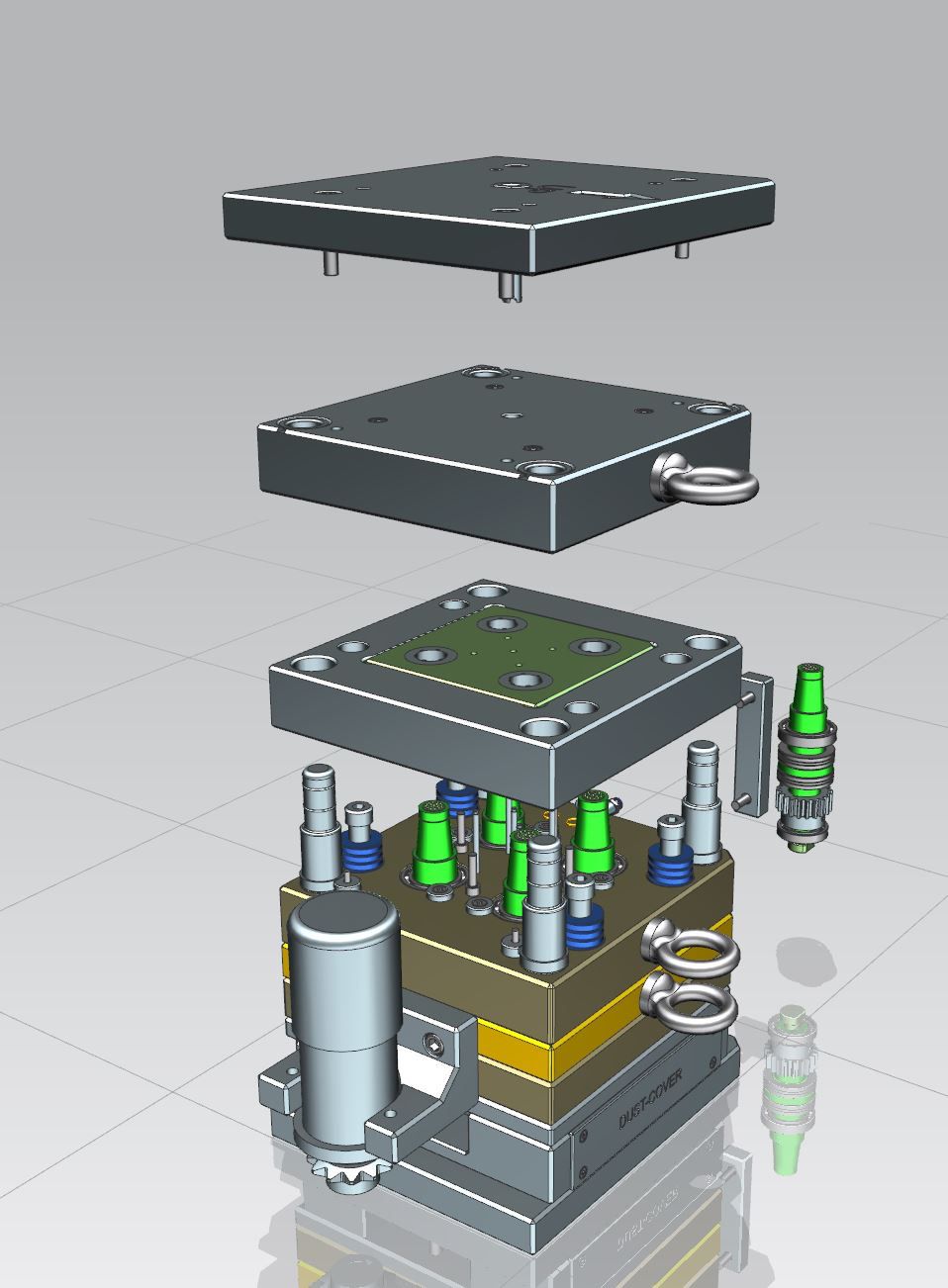

Plastic Injection Mold Design is a manufacturing technology for the mass production of identical plastic parts with good tolerances. In Plastic Injection Mold Design, the polymer granules are first melted and then injected under pressure into a mold where the liquid plastic cools and solidifies.

The materials used in injection molding are thermoplastic polymers that can be colored or filled with other additives.

Almost every plastic part around you has been injection molded: from automotive parts to electronic cabinets to kitchen appliances.

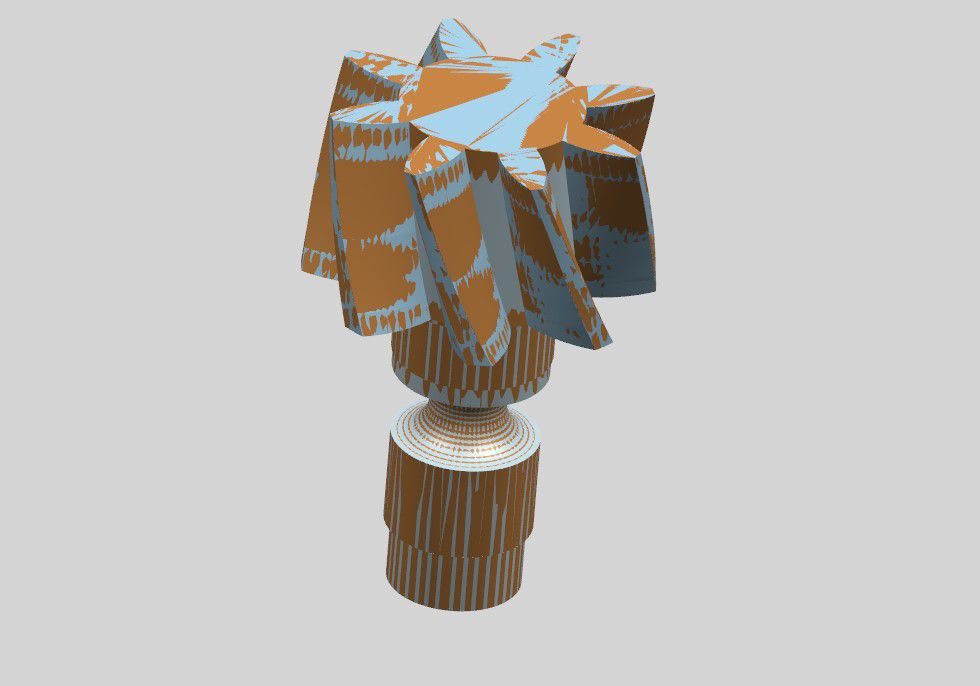

Plastic Injection Mold Design

- INR:

₹21,500₹20,000 - Duration: 40 Days